High Frequency ERW Tube & Pipe Mill Machine

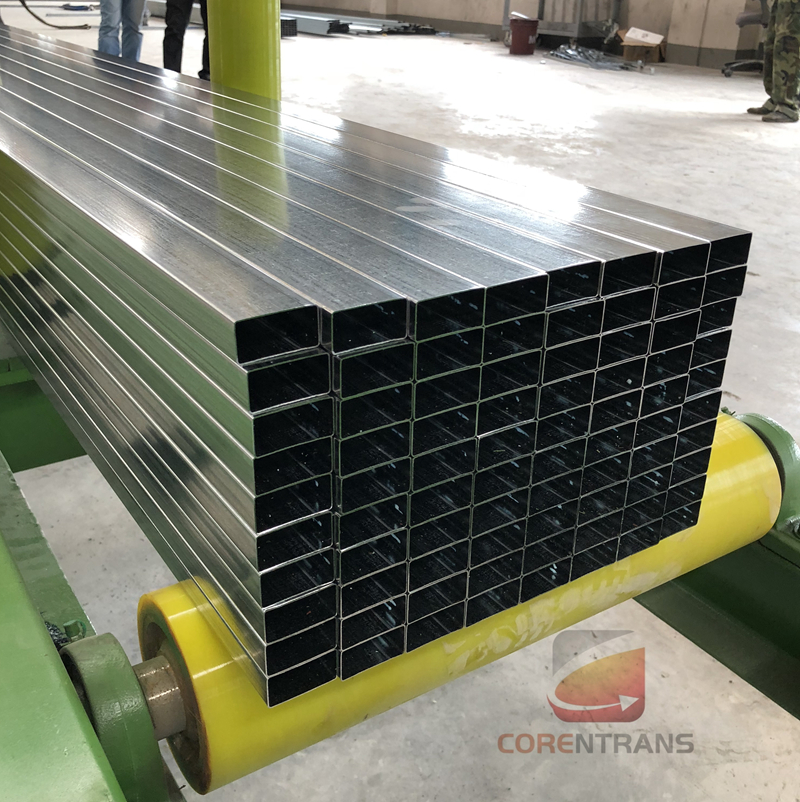

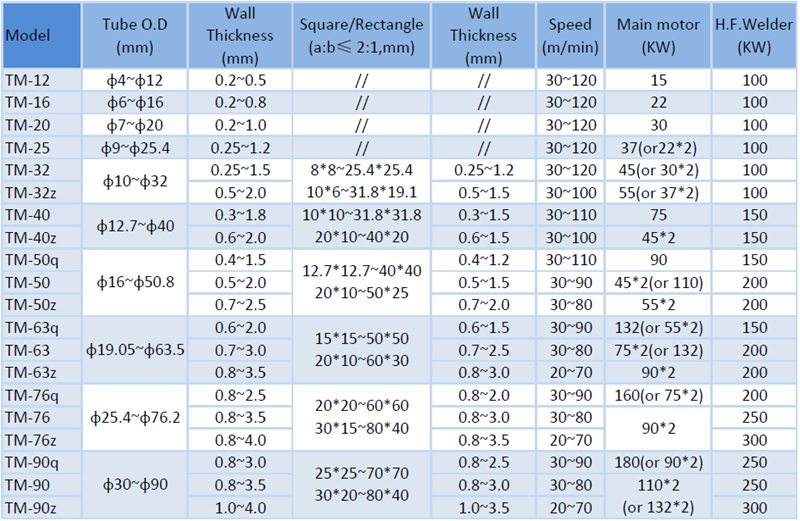

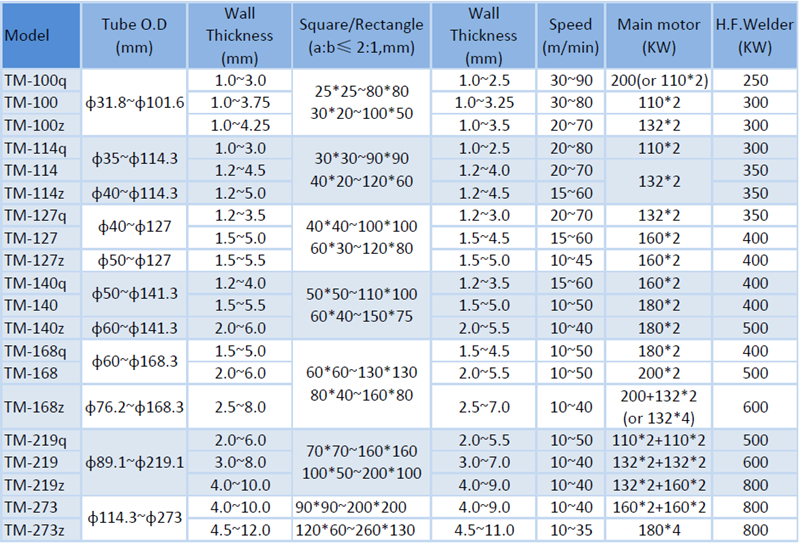

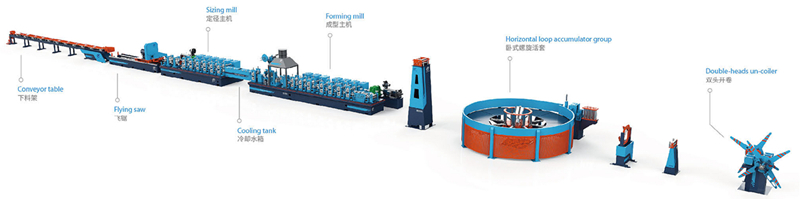

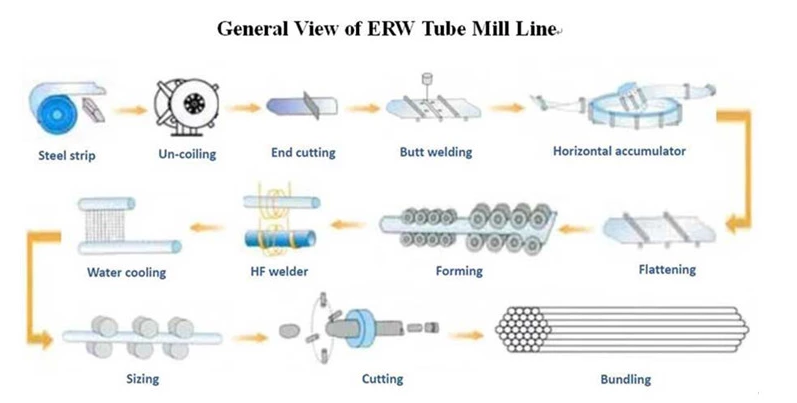

ERW Tube & Pipe Mill Machine Series are the specialized equipment to produce high-frequency straight seam welded pipe and tube for structural pipe and industrial pipe with Φ4.0~Φ273.0mm and the wall thickness δ0.2~12.0 mm. The whole line can reach high precision and high speed through optimization design, best materials choice, and accurate fabrication and rolls. Within a suitable range of pipe diameter and wall thickness, pipe production speed is adjustable.- FLOW CHART

- Features

1. Accumulating more than 20 years of professional manufacturing experience, SHANGHAI COREWIRE INDUSTRY CO., LTD. specialized in supplying TM-12~273 ERW tube mill machine efforts quality improvement and technological researching.

2. Meanwhile, the R&D center featured The ERW tube mill with high-strength design, material selection, precision machining, stable operation, and energy conservation.

- Application:

The products are mainly pipes and tubes used in petroleum, petrochemical, construction, shipbuilding, car making, electric power, mining, coal, machinery manufacturing industries.