| No | Item | Description |

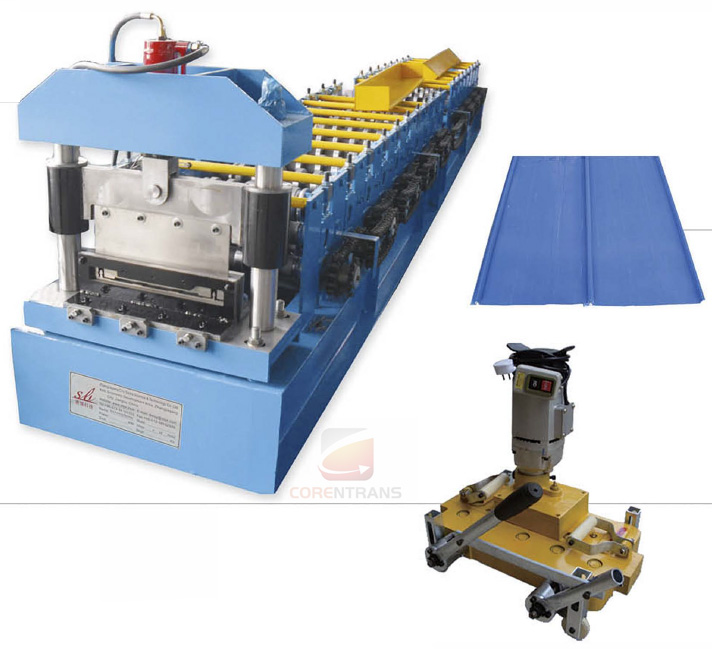

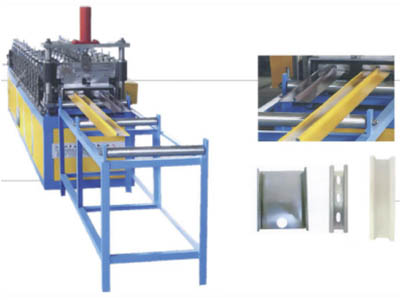

| 1 | Machine structure | Wire-electrode cutting frame |

| 2 | Total power | Motor power-7.5kw Siemens Hydraulic power-5.5kw Siemens |

| 3 | Roller stations | About 12 stations |

| 4 | Productivity | 0-20m/min |

| 5 | Drive system | By chain |

| 6 | Diameter of shaft | ¢70mm solid shaft |

| 7 | Voltage | 415V 50Hz 3phases (Customized) |

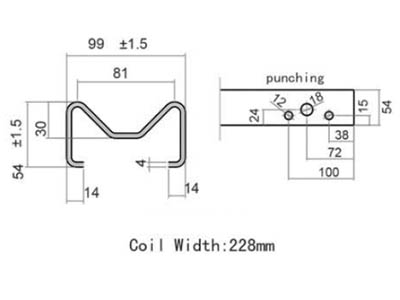

| No. | Specification of the material | |

| 1 | Suitable Material | PPGI 345Mpa |

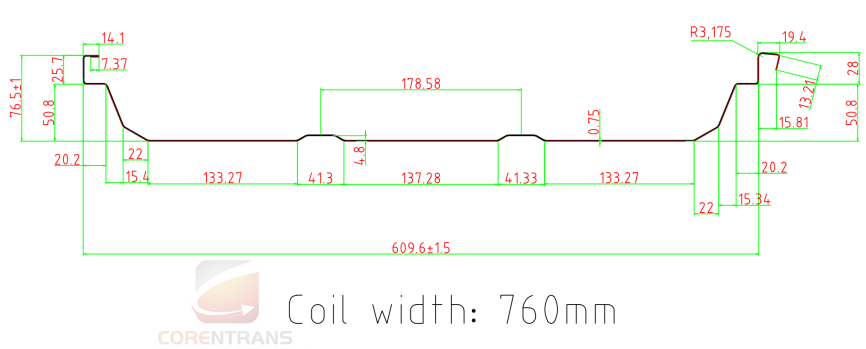

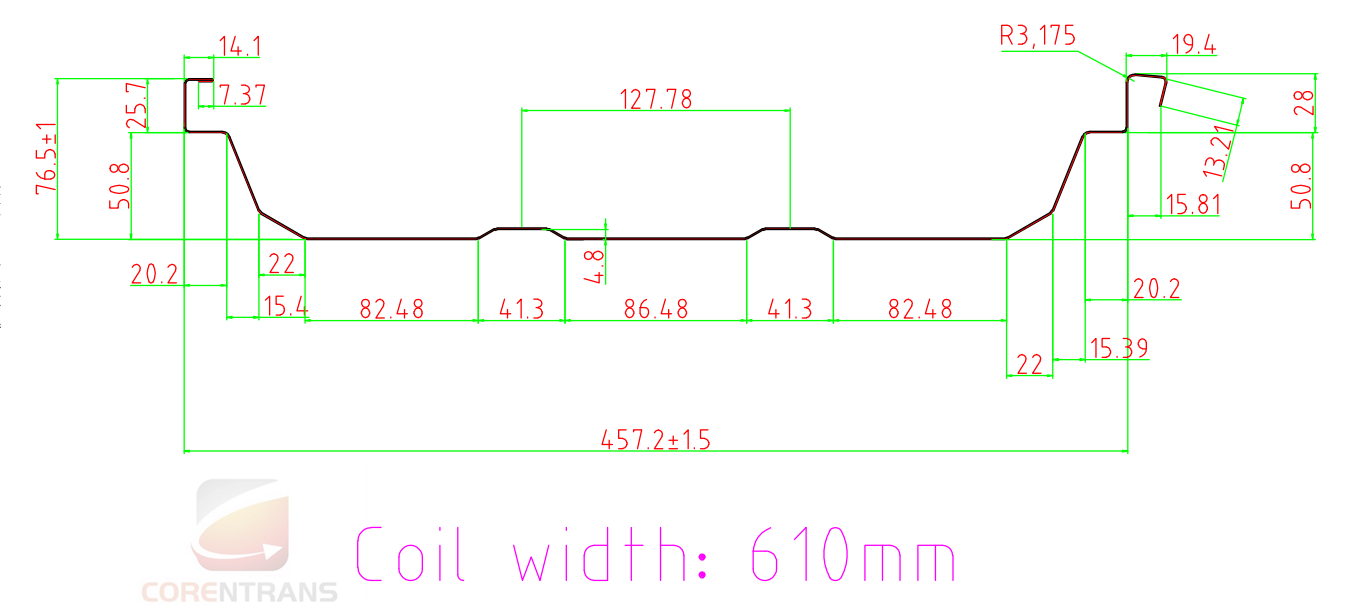

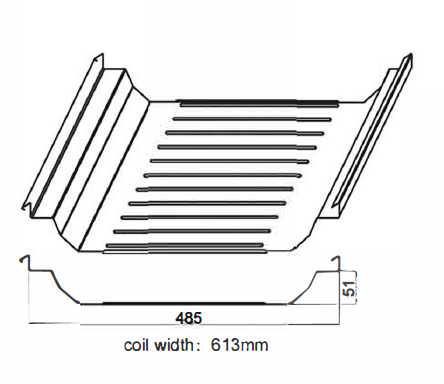

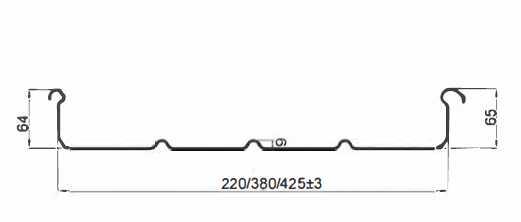

| 2 | Width of the raw material | 610mm and 760mm |

| 3 | Thickness | 0.5-0.7mm |

3T manual Un-coiler—Feeding&ribs—Cutting—Roll Forming—out table

Steel Standing Seam Roll forming Machine is a color-coated steel plate that is cold-rolled into various wave-shaped pressed plates. It is suitable for industrial and civil buildings, warehouses, special buildings, roofs, walls and interior and exterior wall decoration of large-span steel structures. It has the characteristics of light weight, high strength, rich color, convenient and quick construction, anti-seismic, fireproof, rainproof, long life and maintenance-free. It has been widely used.Standing seam roof panel; Standing seam roof sheet; metal roofing sheet; steel roofing sheet; metal roof panel; steel roof panel; metal roof; steel roof; metal roof wall panel; steel roof wall panel;

Steel Standing Seam Roll forming Machine is a color-coated steel plate that is cold-rolled into various wave-shaped pressed plates. It is suitable for industrial and civil buildings, warehouses, special buildings, roofs, walls and interior and exterior wall decoration of large-span steel structures. It has the characteristics of light weight, high strength, rich color, convenient and quick construction, anti-seismic, fireproof, rainproof, long life and maintenance-free. It has been widely used.Standing seam roof panel; Standing seam roof sheet; metal roofing sheet; steel roofing sheet; metal roof panel; steel roof panel; metal roof; steel roof; metal roof wall panel; steel roof wall panel;